Workshop Bench - Rename D & C Multi-Mode Furniture-Makers Bench

Makers will be familiar with the “MFT” or multi-function table which has been around in various forms for a while.

Our Multi-Mode Furniture-Makers Bench takes this concept to a new level with a series of innovative and effective developments, based on our own experience as makers.

Bench

1800mm x 900mm table area provides a generous work surface for precise dimension sawing, routing and moulding, secure handwork and finishing.

Torsion box construction ensures strength and stability along with under-bench accessory storage.

Removable legs to facilitate transport.

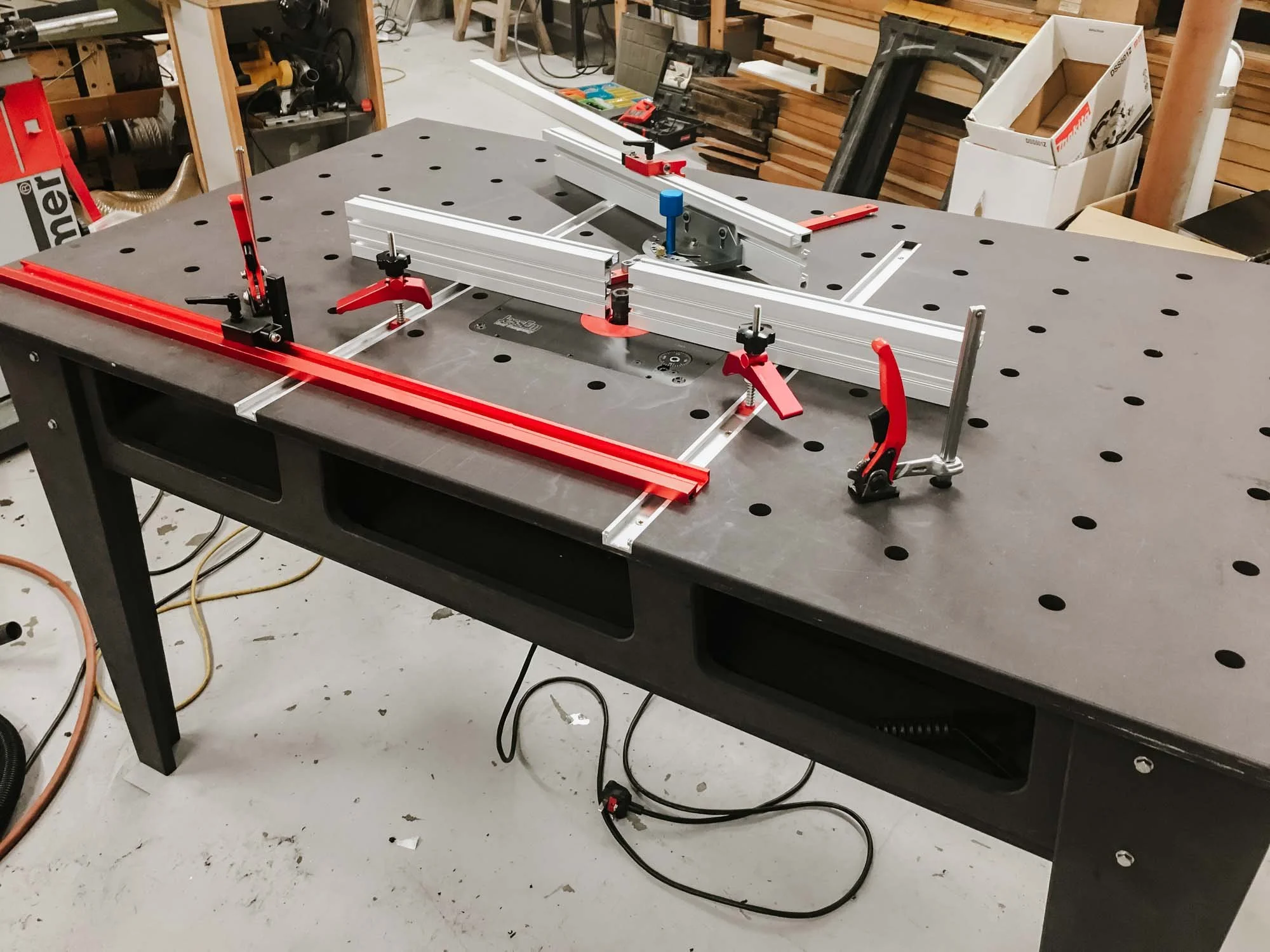

125mm x 20mm CNC-bored, matrix hole pitch, guarantees square machining and minimises clamping interference.

T-Tracks run across the width, rather than the length, of the table for additional functionality.

A side overhang allows free clamping for unusual work pieces all around the table.

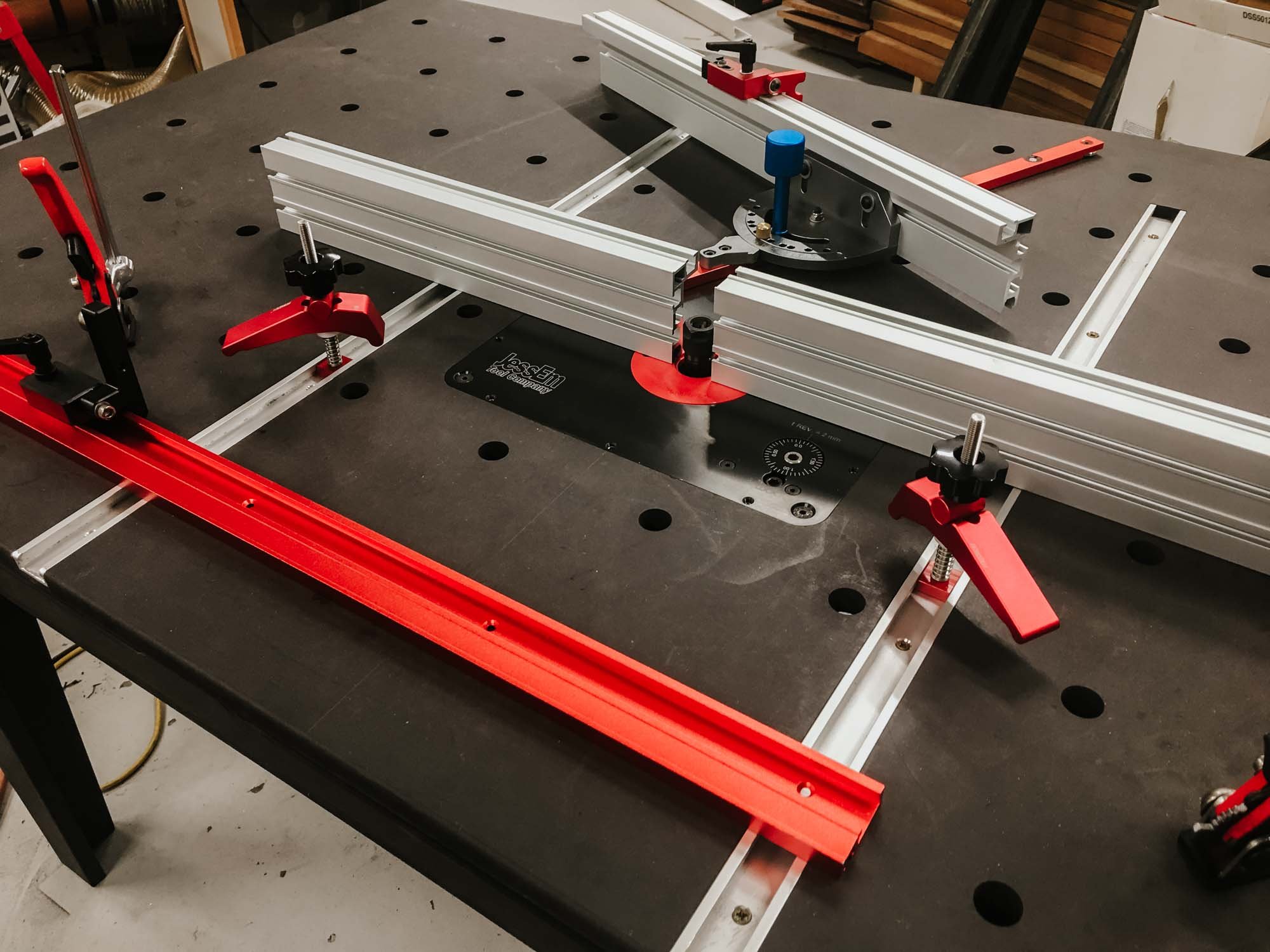

An offset housing, for a standard router lift, is provided, to work in conjunction with the peg board system. This allows a choice of three depths of work surface, to suit different work pieces.

Downdraft dust extraction system with collection chamber access door and standard, Festool®-size, hose port for connection to a portable vacuum or the shop extraction system.

The standard router speed control is accessible via the dust chamber access door.

Under-table storage for saw tracks. Making them available for instant use.

NVR Switch to safely control the router.

240V sockets for power tools.

Dimension Sawing

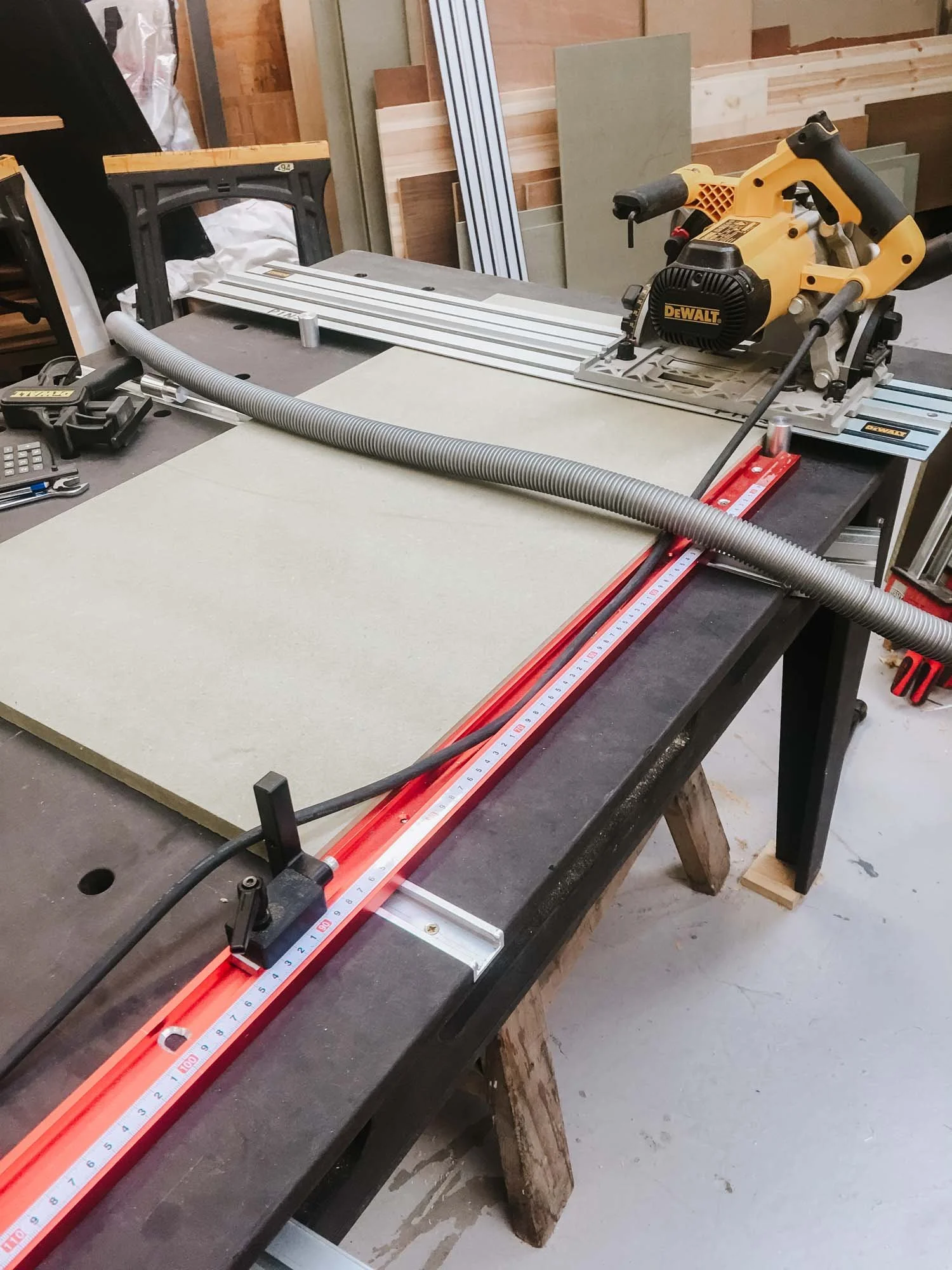

A graduated, T-track fence, with adjustable stop is located on the table, using 20mm buttons in the matrix, allowing precise, repeatable and square dimension sawing of panels up to 1900mm x 800mm without the need to measure or mark.

A range of aluminium pegs is available for work of differing thicknesses. The pegs are a precise fit in the matrix bores to ensure accuracy is maintained.

The system is compatible with all the commercial saw track systems. You may wish to trim the rubber splinter strip, if fitted, to allow the pins direct contact with the track for guaranteed accuracy, but this is optional.

Cross cutting is facilitated across the table.

Rip sawing can be along the table for smaller pieces, or overhanging, using the standard track system for large pieces or full sheets, being maintained at a convenient working height and using the table edge for additional clamping if necessary.

The saw tracks are conveniently located under the table.

Routing, Moulding and Joint cutting.

The table will accept the Jessem type router lift and others of similar dimensions.

No alteration to the router cable is required as a socket and external NVR is provided.

Normal edge moulding and grooving is facilitated by an adjustable fence located in the bench T-slots, or bearing tooling. In both cases dust is drawn downwards into the chamber. Leaving the work area clear.

Usually a collet extension its required for convenience.

Finger boards can be mounted using the same T-slots in front of the fence.

Three different size bench areas are available, front, rear or side, to accommodate the workpiece appropriately.

A 20mm hole to the outfeed side can assist chip clearance in grooving.

For housing and dado work the saw track is used against the pins and the router mounted on the track on a sliding carriage. See below for an adapter for different makes of equipment.

End-grain work

For tenon facing, or other end grain operations such as finger joints, a mitre fence is mounted in the left hand T-Track. This is easier to control and feed rather than the more usual, left to right, across the body methods, used on other tables and can give a clearer view of the cutting action.

In all cases standard 160mm, or higher, table clamps (suitable for a 20mm aperture) are used for secure clamping of the work.